Factories today face immense pressure. They must deliver more, faster, and with perfect quality. Hidden slowdowns in assembly or logistics can cripple output and profits. These bottlenecks are often invisible until it’s too late.

A new approach changes everything. It involves creating a dynamic, virtual model of your entire operation. This model mirrors your physical line in real time.

This virtual replica lets you see the flow of materials and work. You can spot where congestion builds. Leaders can test changes in the simulation first. This eliminates risk and improves throughput before any physical adjustments are made.

The shift is from reacting to problems to preventing them. It connects physical assets with intelligent data streams. This creates a foundation for adaptive, self-optimizing systems.

Key Takeaways

- Hidden production slowdowns severely impact output, cost, and market competitiveness.

- Virtual simulation provides a proactive tool to find and fix bottlenecks before they cause real-world delays.

- A real-time virtual model mirrors physical operations, enabling safe testing of improvements.

- This technology shifts the paradigm from reactive problem-solving to forward-looking optimization.

- Implementing this approach enhances visibility, supports data-driven decisions, and boosts overall equipment effectiveness.

- It represents a core element of modern industrial transformation, creating more responsive operations.

Introduction to Virtual Simulation in Manufacturing

The journey toward operational excellence begins with an accurate virtual representation. This approach builds a dynamic model of your entire production line. It allows for deep analysis and proactive improvement.

Defining Digital Twins and Their Role

A digital twin is a living, virtual replica of a physical system. It synchronizes continuously with real-world equipment and conditions. This model enables predictive analytics and scenario testing.

Its role extends far beyond simple visualization. It transforms how production lines are managed and optimized. Roughly 75% of businesses now use this technology in some form.

The Need for Real-Time Data Integration

Effectiveness hinges on seamless, real-time data integration. Sensors feed information to cloud platforms without delay. This two-way flow ensures the virtual model reflects actual performance.

This immediacy is crucial. It lets teams spot issues and test fixes within seconds. The financial payoff is clear: over 90% of deployments see returns above 10%.

Overview of Digital Twin Technology

The roots of virtual modeling stretch back to ambitious space missions of the mid-20th century. This foundational concept has matured into a powerful tool for modern operations.

It creates a living, data-driven counterpart of physical assets. This allows for unprecedented analysis and foresight.

Evolution from Physical Models to Virtual Replicas

In the 1960s, NASA built full-scale physical duplicates of spacecraft. Engineers used these models to simulate mission scenarios and potential failures.

The 1970 Apollo 13 crisis proved their value. Teams on the ground used the replicas to devise and test life-saving procedures.

A major shift occurred in 2002. Dr. Michael Grieves proposed a framework linking a physical product to its virtual counterpart through continuous data.

This idea moved the concept from static mock-ups to dynamic systems. The term “digital twin” was formally adopted by NASA in 2010.

Today’s versions are a quantum leap forward. They leverage cloud computing and AI to create responsive, predictive models.

This evolution has democratized advanced simulation. It now supports everything from initial design to full-scale production optimization.

Leveraging digital twin, Industrial IoT, Smart Manufacturing, Digital Manufacturing

True operational transformation occurs when separate technological streams converge into a unified system. This integration creates a powerful ecosystem that reshapes production capabilities. Four key pillars work together to make this happen.

Industrial IoT acts as the sensory nervous system for the entire operation. Networks of sensors monitor temperature, pressure, and machine performance. This constant stream of live data feeds directly into the virtual model.

Smart manufacturing takes this information and applies advanced analytics. Artificial intelligence and cloud computing find patterns humans might miss. The result is optimized processes that cut costs and boost product quality.

Digital manufacturing extends this connectivity across the entire value chain. It links product design with production execution and even customer feedback. This creates a unified digital framework from start to finish.

The synergy of these four pillars delivers unprecedented visibility. Leaders gain predictive insights into equipment health and can test changes safely in simulation. This convergence builds a sustainable competitive edge through faster innovation and superior consistency.

Real-Time Production Optimization with Digital Twins

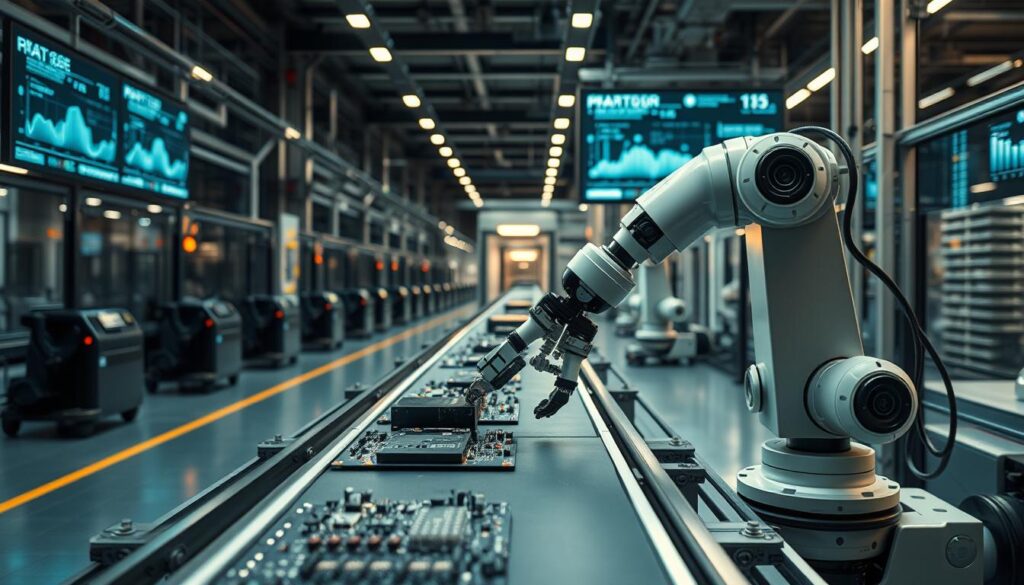

Optimizing a live production line requires more than just historical trends. It demands a living, breathing digital counterpart. This virtual model analyzes every touchpoint continuously.

It spots bottlenecks as they form. Teams get operational insights from live streams, not old reports. This transforms the entire production process.

Utilizing IoT Sensors for Continuous Monitoring

Networks of advanced sensors act as the eyes and ears of the line. They track temperature, pressure, vibration, and flow rates from critical equipment components.

Strategic placement captures comprehensive performance data. This constant flow feeds the virtual model, enabling immediate adjustments to process parameters.

Impact on Overall Equipment Effectiveness (OEE)

This approach directly boosts three key OEE factors: availability, performance efficiency, and quality. Issues are corrected before they cause downtime.

Manufacturers see measurable gains in throughput and yield. Resource utilization improves while waste drops across operations, raising overall efficiency.

| Aspect | Traditional Approach | Digital Twin Approach |

|---|---|---|

| Data Source | Historical records & manual logs | Live sensor streams & real-time analytics |

| Response Time | Days or weeks for analysis | Seconds for detection and alert |

| Optimization Scope | Isolated equipment adjustments | Whole line balancing and workflow sequencing |

| Impact on OEE | Incremental, slow improvements | Substantial, continuous gains in availability, performance, quality |

The closed-loop feedback between the virtual and physical worlds creates a self-optimizing production system that learns and adapts.

Predictive Maintenance and Data-Driven Insights

Moving beyond scheduled maintenance requires a leap into predictive intelligence. This approach uses data to foresee machine issues long before they cause stoppages.

It transforms upkeep from a cost center into a strategic advantage. Teams gain actionable insights to optimize asset health and uptime.

Machine Learning Algorithms in Maintenance

Advanced algorithms analyze live sensor streams and historical logs. They learn normal equipment behavior and spot tiny anomalies.

These patterns signal wear or impending failure weeks in advance. This allows for planned repairs during downtime, not emergency fixes.

| Maintenance Approach | Core Principle | Data Usage | Typical Outcome |

|---|---|---|---|

| Reactive | Fix it when it breaks | None | High downtime, costly repairs |

| Preventive | Schedule fixes on a calendar | Basic time logs | Reduced failures, but some wasted effort |

| Predictive | Act on condition-based alerts | Real-time sensor analytics | Maximized uptime, lower costs, longer asset life |

The digital twin is central to this system. It continuously compares real-world performance against the virtual model’s predictions.

This creates a powerful feedback loop. Maintenance becomes a precise science, boosting reliability and cutting expenses.

Smart Manufacturing: Enhancing Efficiency and Quality

Modern production floors achieve new levels of precision by connecting every element of the operation. This interconnected ecosystem allows machines, enterprise software, and supply chain networks to communicate seamlessly.

Unified intelligence enhances efficiency across all processes. It enables rapid adaptation to new customer demands without major retooling, boosting overall efficiency.

Automated Workflows and Quality Control

Automation orchestrates complex sequences based on real-time conditions. This eliminates manual handoffs and reduces human error, accelerating production cycles.

Control transforms from final inspection to continuous monitoring. AI-powered visual systems analyze data streams to detect defects as products move through the line.

Integrating analytics with control systems enables immediate corrective actions. This prevents defective items from advancing, cutting scrap rates and rework costs while ensuring final quality.

These approaches optimize resource use and minimize waste across processes. They provide leaders with clear visibility into performance metrics for informed decision-making across operations. Advanced analytics track energy use and material flow, supporting sustainable operations.

Harnessing AI and Advanced Analytics in Manufacturing

The next frontier in production line mastery lies in the fusion of artificial intelligence with deep analytical power. These technologies process immense streams of live sensor data, uncovering patterns and predicting issues with superhuman speed.

AI-Driven Simulation and Process Optimization

Sophisticated simulation capabilities allow teams to test thousands of production scenarios virtually. This evaluates how different process parameters impact efficiency and cost before any physical change is made.

Advanced analytics platforms autonomously adjust equipment settings and material flows. This continuous optimization refines systems without constant human oversight, driving incremental performance gains.

The strategic value extends beyond the factory floor. Comprehensive analysis informs critical business decisions on product design and supply chain strategy. Analytics engines generate actionable insights, recommending optimal production volumes and resource allocation.

This creates a self-improving operational environment. Manufacturers gain a competitive edge through faster, more accurate decisions and the ability to spot hidden innovation opportunities within complex data.

Integrating IIoT and SCADA for Real-Time Data Capture

The backbone of any responsive production system is a robust data capture infrastructure. It must connect established control technology with modern sensor networks.

Bridging Legacy Systems with Modern Technologies

Legacy SCADA systems hold decades of operational knowledge. Successful integration preserves this functionality while adding modern connectivity.

Unified Namespace architecture is key. It eliminates data silos between SCADA, execution platforms, and business systems.

This creates a single, reliable source of truth. All platforms and people work from the same live data.

Edge computing places processing power close to equipment. This reduces latency for immediate, local decision-making when conditions change.

Strategic placement of modern sensors is critical. They monitor temperature, pressure, vibration, and flow rates across operations.

The final challenge is harmonizing diverse protocols and formats. A unified framework ensures consistent data flows to analytics platforms.

This integration delivers real-time visibility. It turns raw information into actionable insights for superior control.

Simulating Production Scenarios and Bottleneck Identification

Unlocking peak operational flow requires a sandbox where every change can be tested without consequence. This is the core promise of advanced scenario analysis. Teams move beyond guesswork to validate ideas in a dynamic virtual environment.

What-If Analysis and Virtual Testing

What-if analysis empowers teams to explore countless scenarios. They can model new product introductions or major line rebalancing. Each virtual experiment evaluates impacts on throughput, cost, and quality before any physical resource is committed.

This testing occurs in a risk-free space. For example, a team can simulate an assembly line upgrade to see its effect on downstream operations. They assess performance under various conditions without disrupting live production.

The process rapidly identifies constraint points where flow restricts overall output. This analysis reveals true bottlenecks, enabling targeted interventions. Teams focus improvements where they deliver maximum impact on system performance.

Virtual simulation accelerates optimization cycles, letting teams evaluate dozens of potential improvements in the time previously needed for one physical change.

This capability extends beyond equipment. It encompasses workforce scheduling, material flow, and quality strategies. The virtual twin validates hypotheses with high confidence, ensuring modifications work under real conditions. This approach minimizes costly mistakes and drives continuous refinement of the entire process.

Digital Twin Implementation Strategies in Modern Factories

A successful rollout of this advanced modeling technology hinges on meticulous planning and phased execution. Leaders must build a robust framework that grows from a focused pilot to plant-wide transformation.

Phased Approach from Pilot to Scale

The journey begins with a foundation phase. Teams audit existing information infrastructure and prioritize high-impact use cases. This stage sets the cybersecurity and architectural blueprint.

Next, a pilot targets critical equipment. Sensors are deployed to feed live performance metrics into initial models. Validation here proves accuracy and builds confidence for broader rollout.

Scaling expands the sensor network across additional assets. Advanced analytics and enterprise connections are integrated. This phase develops automated optimization algorithms for continuous improvement.

Technology Architecture and Data Integration

A three-layer architecture supports these virtual replicas. The acquisition layer pulls information from sensors, SCADA, and business platforms.

The processing layer uses edge and cloud resources to analyze streams. Analytics engines find patterns and predict outcomes.

The application layer delivers tools for visualization and optimization. Seamless information integration across these layers is critical. It ensures the model reflects true physical conditions for reliable insights.

Overcoming Challenges in Smart Manufacturing Integration

Integrating advanced technologies into existing factory floors presents a complex set of hurdles that demand strategic navigation. These obstacles are both technical and organizational. They can stall progress if not addressed with a clear plan.

Data quality is a foundational issue. Inconsistent formats and siloed information disrupt seamless integration. Automated validation and master data management are essential for reliable systems.

Managing Cybersecurity and Legacy Systems

As operational and information technology converge, the attack surface expands. Robust cybersecurity frameworks are non-negotiable. They protect sensitive data and physical operations from breaches.

Integrating legacy infrastructure is another major hurdle. Older SCADA platforms and controllers often use proprietary protocols. Bridging these to modern cloud technology requires careful strategy.

Skills gaps and change resistance are human challenges. Strategic partnerships with experienced integrators help. Phased implementation allows teams to adapt to new processes.

Overcoming these barriers builds a sustainable competitive edge. It creates manufacturing capabilities that are difficult for rivals to replicate. The discipline required pays off in resilient, optimized processes.

Digitizing the Manufacturing Process: From Plant to Cloud

The key to a responsive operation is a unified data framework that bridges local control with global analytics. This framework establishes a complete data pathway from sensors on the shop floor to powerful off-site computing resources.

This end-to-end flow creates total visibility and command over geographically spread operations. It turns raw machine signals into strategic intelligence.

Unified Namespace (UNS) and Edge Computing

Unified Namespace architecture is the cornerstone. It eliminates traditional data silos separating SCADA, MES, ERP, and sensor networks.

Instead, it creates a single, authoritative source of truth. All platforms and people access the same live information, enabling seamless integration.

Edge computing places processing power physically close to production equipment. This allows for immediate, local decision-making when conditions change rapidly.

It filters and summarizes data before sending it upstream. This reduces network latency and keeps critical systems running smoothly.

Cloud technology provides the scalable backbone for storage and complex analysis. It supports advanced models and enables remote monitoring from anywhere.

Virtual twins leverage this hybrid setup. They sync with edge data in real-time while using cloud power for heavy simulations.

This architecture ensures business continuity and supports a resilient, future-proof operation.

Industrial Transformation and Supply Chain Resilience

Global market volatility has thrust supply chain resilience into the strategic spotlight for modern industry. External shocks from geopolitics to natural disasters now threaten business continuity. This makes robust supply networks a board-level priority.

Industrial transformation through connected platforms fundamentally strengthens this resilience. It provides real-time visibility into material flows and inventory across extended supplier networks. Leaders gain a clear view of production capacity and logistics operations.

Enhancing Visibility and Reducing Disruptions

Virtual models now extend beyond single facilities to map entire supply chain ecosystems. They simulate how disruptions at supplier locations or transportation bottlenecks impact production. This allows for proactive planning before constraints halt lines.

Enhanced visibility lets teams track raw material levels and monitor supplier status. They can anticipate delivery delays and identify alternative sourcing options. This proactive approach reduces costly stoppages.

Integration with planning systems creates closed-loop coordination. Production schedules adjust automatically based on material availability. Procurement systems respond to real capacity changes and demand forecasts.

Predictive analytics applied to supply chain data identify emerging risks. These include supplier instability or regional disruption potential. Teams can enact mitigation strategies before problems materialize.

Organizations leveraging this transformation see measurable gains. They achieve better on-time delivery and higher inventory turnover. This creates adaptive networks capable of rapid reconfiguration.

Emerging Trends and Future Outlook in Digital Twin Technology

Market projections reveal an astonishing trajectory for virtual replica technology, signaling its move from niche tool to industrial cornerstone. Analysts forecast growth from $24.5 billion in 2025 to over $259 billion by 2032.

This expansion is driven by accelerating adoption across aerospace, healthcare, and infrastructure sectors. Nearly 30% of companies had implemented strategies by 2023.

Generative AI and Autonomous Optimization

Generative AI represents the most transformative trend. It enables these models to predict future system behaviors and generate optimization recommendations.

Advanced AI models empower digital twins to make complex, multi-step decisions autonomously. They can anticipate cascading failures and implement operational changes without human intervention.

Delivery models like Digital Twin as a Service (DTaaS) democratize access through the cloud. This allows for rapid deployment without major upfront investment.

Future applications will extend to modeling human cognition and behavior for workforce optimization. The convergence with blockchain and 5G will unlock real-time optimization of globally distributed operations.

Organizations at the forefront of these trends will establish a decisive competitive edge. They will redefine production economics and market responsiveness in the future.

Case Studies and Industry Success Stories

Real-world evidence from top-tier companies demonstrates the powerful impact of advanced simulation technology. A 2025 survey reveals that 92% of deploying companies report returns above 10%. Over half achieve ROI exceeding 20%.

Examples from Leading Manufacturers

Aerospace manufacturers used virtual models to slash development cycles by 40%. They cut physical prototype needs by 60%. This boosted final product quality significantly.

In the automotive industry, production lines saw 25% higher throughput. Changeover times dropped by 35%. These improvements stemmed from precise bottleneck identification.

Quantifiable ROI and Performance Improvements

Operational gains are clear and measurable. Overall Equipment Effectiveness often rises 15-25%. Mean Time Between Failures extends by 30-40%.

First-Pass Yield improves 10-15%. Energy efficiency gains reach 20-30%. These metrics directly lower operational costs.

| Metric Category | Key Indicators | Typical Improvement |

|---|---|---|

| Operational | OEE, MTBF, Yield | 15-40% |

| Business | Cost per Unit, Time to Market | 12-50% |

Business performance also soars. Cost per unit falls 12-18%. Time to market accelerates 30-50%. Management teams report 98% satisfaction with these projects.

Measurable ROI typically appears within 18 months. Successful companies focus on high-impact use cases and experienced partners. This ensures 95% on-budget delivery.

Conclusion

Looking ahead, the ability to simulate and optimize will define leadership in manufacturing. Virtual simulation through digital twins represents a fundamental transformation. It changes how companies identify bottlenecks and enhance their production lines.

The convergence of this technology with advanced analytics creates integrated ecosystems. They deliver measurable gains in efficiency, quality, and cost. Organizations that adopt this strategy gain a sustainable competitive edge in their industry.

With over 90% of deployments showing positive returns, delay carries significant risk. Future success will depend on the power to test scenarios and predict issues. Leaders should begin with strategic planning and phased rollouts.

FAQ

What exactly is a virtual replica of a production line?

A virtual replica is a dynamic, software-based model of a physical production line. It uses real-time data from sensors and systems to mirror the actual operations. This allows engineers to visualize, analyze, and simulate the entire process to improve performance and find problems before they occur.

How does this technology help with predictive maintenance?

By continuously feeding operational data from equipment into the virtual model, analytics platforms can detect subtle changes. These changes signal potential failures. This data-driven approach allows teams to schedule maintenance precisely when needed, avoiding costly unplanned downtime and extending machine life.

Can these models integrate with older factory systems?

Yes, a key strength is integration with legacy infrastructure. Modern platforms act as a bridge, pulling data from traditional SCADA and control systems. This creates a unified view of operations without requiring a full, immediate replacement of existing assets, protecting prior investments.

What role does AI play in optimizing manufacturing processes?

Artificial Intelligence and machine learning algorithms analyze vast amounts of process data from the virtual model. They identify patterns and correlations humans might miss. This enables autonomous optimization of settings for better quality, higher efficiency, and reduced costs.

How do virtual replicas improve supply chain resilience?

They provide end-to-end visibility. By modeling not just the factory floor but also logistics and inventory flows, companies can simulate disruptions. This “what-if” analysis helps leaders make better decisions, adjust sourcing, and reroute logistics to minimize disruptions and maintain operations.

What is a common first step for a company implementing this solution?

A successful strategy typically starts with a focused pilot project. Companies like Siemens often begin by modeling a single, critical production line or piece of equipment. This proves the value, builds internal expertise, and defines the technology architecture for a broader, scalable rollout across the factory.

Are there measurable returns on investment from using this approach?

Absolutely. Industry leaders report significant ROI. For example, NVIDIA highlights use cases where virtual models have boosted Overall Equipment Effectiveness (OEE) by double digits. Tangible benefits include major reductions in downtime, lower energy consumption, fewer quality defects, and faster time-to-market for new products.

How Iottive Delivers End-to-End IIoT Solutions

1. Concept & Solution Design

Iottive works closely with plant teams, engineering leaders, and stakeholders to understand operational challenges, asset behavior, and production goals. This phase includes use-case validation, system architecture design, sensor selection, connectivity planning, and defining measurable business outcomes.

2. Engineering & System Integration

Iottive engineers industrial-grade IIoT solutions by integrating sensors, PLCs, SCADA systems, gateways, and industrial protocols such as OPC UA, Modbus, MQTT, and BLE. The focus is on reliable data acquisition, secure communication, and seamless integration with existing automation infrastructure.

3. Prototyping & Pilot Deployment

Rapid prototyping enables manufacturers to validate concepts on the shop floor before full-scale rollout. Iottive develops functional prototypes, edge analytics, dashboards, and mobile applications to test performance, data accuracy, and operational feasibility in real manufacturing environments.

4. Product Experience & Data Intelligence

Iottive designs intuitive web and mobile dashboards that provide real-time visibility into machine health, production metrics, and operational KPIs. Advanced analytics, alerts, and visualization tools empower plant teams to take proactive, data-driven decisions with minimal complexity.

5. Commercialization & Scale-Up

From MVP to enterprise deployment, Iottive supports product hardening, scalability, cloud or hybrid deployments, and long-term maintenance. Solutions are designed for multi-plant rollout, system expansion, and continuous optimization—ensuring measurable ROI and operational impact.

Why Manufacturers Choose Iottive

- Proven experience in Industrial Automation & IIoT

- Strong understanding of real shop-floor challenges

- Seamless integration with existing PLC/SCADA systems

- Scalable, secure, and production-ready architectures

- Focus on business outcomes, not just technology

📧 Contact Email: sales@iottive.com