On a rainy afternoon, a local courier watched a small delivery craft reroute around a worksite thanks to a last‑minute adjustment sent from the cloud. That quick fix avoided a return trip and a costly service call. It also highlighted how modern fleets rely on remote software and firmware delivery to stay safe and reliable.

Cloud-based update pipelines make it possible to roll out new features, enforce compliance, and deliver security patches to fleets at scale. With secure transport, signed packages, and dual-partition rollback, teams can deploy changes without grounding missions.

Iottive’s experience in BLE apps, cloud integration, and custom platforms shows how integration between cloud, edge computing, and local systems turns raw data into near‑real‑time decisions. This approach reduces service truck rolls, speeds feature delivery, and keeps operations compliant across regulated airspace.

Key Takeaways

- Cloud pipelines enable zero‑touch deployments and safe rollbacks.

- Signed packages and encrypted transport are baseline security.

- Edge computing cuts response time and lowers bandwidth use.

- Remote tuning and predictive maintenance boost fleet efficiency.

- Standard protocols and robust system design prevent failures during installs.

Why Continuous Updates Matter for Delivery Drones in a Hyperconnected Future

Regular, cloud-driven rollouts keep delivery fleets resilient as software, regulations, and threats evolve.

Over 29 billion connected devices are expected to rely on remote patching by 2030, which shows the scale of the challenge for modern delivery systems. Continuous delivery protects fleets from emerging vulnerabilities and ensures ongoing security and compliance as policies and dependencies shift.

Frequent, small packages reduce service interruptions. Background downloads, incremental payloads, and staged switchovers cut downtime and let operations remain on schedule. These approaches also lower manual service costs and keep mission times predictable.

Maintaining synchronized software across varied environments avoids version drift and fragmented systems. That consistency improves energy use, preserves SLAs, and builds customer trust in on‑time delivery performance.

- Continuous delivery encodes policy changes and audit logs for regulators and risk teams.

- Common challenges include variable connectivity, fragmented systems, and version drift.

- Iottive’s integration expertise streamlines cross‑platform rollouts to sustain security and compliance without heavy overhead.

Next: the architecture and security pipeline design that make continuous updating practical at scale.

From Ground Crews to the Cloud: What Over‑the‑Air Means for Drone Fleets

Moving routine servicing from depots to a central platform transforms how fleets stay mission‑ready.

Fleet operators cut costs and time by avoiding truck rolls and depot visits. Remote distribution schedules installs during charging or low‑use windows to prevent lost delivery time.

Centralized management scales to thousands of aircraft using staged rollouts, policy controls, and dashboards for version tracking. Incremental packages and multicast reduce file sizes and network bills.

Dual‑partition installs with automatic rollback preserve uptime and prevent bricking. Queued downloads resume after interruptions and verify integrity before switching to the new image.

“Automated validation on first boot and edge processing turn a nightly patch into a safe, low‑risk maintenance window.”

- Cost and time: fewer truck rolls, lower cellular/SATCOM costs via delta packages.

- Uptime: rollback and dual partitions reduce mission failures and downtime.

- Operations: scheduling and orchestration unify hubs to avoid peak‑hour disruption.

- Resilience: edge computing enables fast checks and post‑install self‑tests.

| Challenge | Cloud Solution | Benefit |

|---|---|---|

| High field service costs | Remote distribution, multicast, delta packages | Lower costs, faster rollouts |

| Interrupted downloads | Queued resumes with integrity checks | Safe installs, fewer failures |

| Risk of bricking | Dual‑partition + automatic rollback | Improved uptime |

| Bandwidth limits on missions | Edge processing and incremental payloads | Reduced data use, faster processing |

Example: a regional delivery fleet pushes a battery‑management patch overnight via multicast. Devices validate the image on first boot and report telemetry. Management sees success rates in the dashboard and schedules any remedial work during daytime lulls.

Iottive combines cloud/mobile integration with on‑device processing so teams centralize control while keeping flexibility for routes, hubs, and SLAs. That pairing turns maintenance data into proactive fixes before issues become field failures.

Inside a Robust Drone OTA Architecture

A reliable update architecture puts the server and device client in clear, complementary roles to keep fleets safe and mission-ready.

Server role: the authoritative system hosts signed software packages, authenticates devices, and schedules staged rollouts. It manages policy, maintains the repository, and pushes telemetry-based approvals during canary phases.

Device client: the execution agent requests packages, verifies signatures and checksums, and performs installs on the inactive partition. Clients report health checks and rollback triggers to the server after first boot.

Secure transport and resilience

TLS via HTTPS, MQTT, or CoAP encrypts data in transit. Signed artifacts and hash-based integrity checks prevent tampering. Power-loss resilience and partial-download resumption protect against failures during install.

Efficiency, storage, and monitoring

Dual-partition design allows instant switch and automatic rollback if post-install checks fail. Incremental (delta) packages and multicast delivery save bandwidth for clustered hubs.

| Capability | How it works | Benefit |

|---|---|---|

| Diff & decompress algorithms | BSDiff, zstd chunking | Faster processing, smaller storage footprint |

| Repository & CDN | Scaled stores + edge nodes near hubs | Lower latency, reduced transfer costs |

| Hardware checks | Staging storage, sensor health, thermal limits | Prevents installs that stress components |

| Canary rollout | 1% → telemetry → 10% → general | Limits downtime and operational risk |

Operations and maintenance integrate with dashboards for compliance logging, exception handling, and automated ticketing. This infrastructure supports safer deployments and clearer audit trails for future maintenance.

Choosing Centralized, Edge-Based, or Hybrid Update Models

Picking the right model starts with where you operate and how the fleet communicates.

Centralized cloud control: simplicity vs. bottlenecks

Centralized systems simplify management and integration. They work well for small to medium fleets with stable connectivity.

At scale, however, a single control plane can create bandwidth and scheduling bottlenecks. That raises costs and increases the risk of delayed installs.

Edge distribution: latency cuts for large fleets

Edge-based models move packages to local nodes near hubs. This reduces latency and eases long-haul data transmission.

Local caching and multicast lower backhaul use and speed routine rollouts. Edge computing also enables store‑and‑forward where connectivity is intermittent.

Hybrid orchestration: balancing scale, cost, and resilience

Hybrid orchestration keeps critical controls centralized while routing routine packages through regional edge servers.

This approach balances infrastructure trade‑offs: CDN vs. dedicated edge hardware, storage needs, and automated deployments across geographies.

| Model | Best for | Key benefits |

|---|---|---|

| Centralized | Small/medium fleets | Simple management, unified policy, lower integration overhead |

| Edge-based | Large regional fleets | Reduced latency, lower data transmission, local multicast |

| Hybrid | Nationwide networks | Scalable control, cost optimization, resilience with local caching |

- Operations gains: localized monitoring, autonomous scheduling, and repair window alignment.

- Hardware needs: caching, cryptographic validation, and secure access at edge nodes.

- Applications: hybrid models excel where connectivity varies and urgent fixes are required.

Security First: Hardening the Update Pipeline End to End

Protecting the delivery pipeline starts with building identity and integrity controls into every layer of the system.

Authentication, signatures, and integrity checks

Signed packages and hash validation ensure software comes from a trusted build and remains unchanged in transit. Mutual authentication between servers and devices prevents unauthorized pushes.

Use TLS transport, strict cipher suites, and package signing from the build server through to device installation. Dual‑partition rollbacks and post‑install health checks reduce the risk of mission‑critical failures.

Zero‑trust device identity and encrypted storage

Zero‑trust means unique device identities, mutual certs, and least‑privilege access by default. Certificate rotation and short-lived tokens keep long‑lived fleets manageable.

Store keys and artifacts in encrypted storage or secure enclaves (TPM‑like hardware) to resist tampering and theft. Iottive implements these controls for regulated environments to help maintain compliance.

Mitigating cybersecurity risks in networked systems

- Processing safeguards: pre‑install dependency validation, memory and storage checks, and policy gates to prevent corrupted installs.

- Operational controls: role‑based access, audit trails, alerting, and SOC integration for faster incident response.

- Continuous hygiene: SBOM tracking, vulnerability scanning, and automated patch workflows to close emerging issues.

Edge considerations are essential: secure edge caches, certificate pinning, and encrypted channels between regional nodes and central servers preserve integrity across distributed computing and operations.

Regulatory and Safety Considerations for U.S. Operations

Maintaining safety in national airspace requires systems that push rule changes and proof-of-installation records in real time.

Coordinating with UTM and airspace restrictions in real time

Integration with UTM and ATC feeds lets fleets receive temporary flight restrictions and reroute missions quickly.

Policy packages can encode geo-fencing, altitude caps, and speed limits so devices enforce constraints automatically.

An immediate route change can be delivered, validated, and enforced before a mission deviates from compliance.

Documentation, audits, and maintaining compliance via remote policy delivery

Iottive supports audit-ready logging that records who approved each build and when each device installed it.

Complete logs, test evidence, and retained artifacts form automated audit packages for regulators and partners.

Version pinning, rollback reports, and device identity proofs provide traceability for every change.

- Safety outcomes: rapid policy changes adjust max altitude, speed, and no‑fly zones fleetwide.

- Management value: timestamped approvals and install success data reduce audit friction.

- Operational readiness: training materials and emergency procedures can be pushed to crews to keep practices consistent.

- Resilience: edge caches preserve policy availability when backhaul connectivity is limited in the field.

Monitoring and analysis dashboards surface noncompliant devices for remediation before flight, shortening response time and improving mission safety.

Edge Computing: The Update Accelerator for Real-Time Drone Decisions

Local computing turns raw sensor streams into instant actions, shrinking decision loops from seconds to milliseconds.

Onboard inference runs models close to the sensors so obstacle avoidance, route changes, and anomaly detection happen immediately. This cuts response time and preserves mission continuity when backhaul is slow.

Workflow: capture, on-site processing, and platform integration

First, multi-sensor capture records RGB, thermal, LiDAR, and multispectral data. Second, local processing filters and summarizes the data into compact alerts.

Third, summaries sync with cloud platforms for fleet-wide visibility and longer-term analysis. Iottive engineers SWaP-aware edge solutions that link field inference with mobile and cloud integration.

SWaP-aware hardware, connectivity, and resilience

Lightweight accelerators (Jetson, Movidius, Snapdragon), SSD staging, and fanless enclosures balance weight and endurance. Connectivity options include Wi‑Fi, LTE, and 5G, with hybrid models sending only summaries to save bandwidth.

- Algorithms tuned for embedded inference trade accuracy for energy to protect mission time.

- Built-in monitoring validates model health after remote model installs and detects drift.

- Geotagged alerts, path optimization, and automatic re-tasking enable faster, autonomous responses.

“Edge cuts response from seconds to milliseconds, enabling near‑real‑time human detection in field SAR use cases.”

AI Drone Performance Tuning in the Field

In-field model distribution shortens the gap between lab training and real-world behavior under varied weather and lighting.

Onboard model updates push refined models to vehicles so navigation, object tracking, and precise landings improve from actual mission data. Edge-based vision and lightweight processing let systems react locally with low latency.

Embedded algorithms are tuned for energy and compute constraints. Quantization, pruning, and memory allocation balance accuracy and flight endurance while keeping inference fast.

- Training workflows use fleet telemetry and annotated clips to raise detection confidence and cut false positives.

- Federated learning keeps raw footage on-device and shares gradients to improve global models while preserving privacy.

- Sensor fusion—RGB, thermal, and LiDAR—boosts robustness in low light and bad weather.

Safety and lifecycle practices include canary A/B tests, model versioning, and rollback of weights if metrics degrade. Operational playbooks validate releases on test routes before general release.

Iottive integrates data labeling, BLE-connected tools, cloud/mobile pipelines, and monitoring so teams close the loop from capture to deployment and see real gains in field performance and safety.

Predictive Maintenance Powered by IoT Sensors and ML

Smart sensor arrays and machine learning flag subtle changes in motors and batteries that humans can miss.

Health telemetry: motors, batteries, stress, and environment

Define a simple telemetry stack that streams vibration, motor RPM, temperature, battery voltage/current, structural strain, and ambient conditions. Short, secure software agents collect and encrypt this data for local and cloud processing.

Anomaly detection to prevent failures and reduce downtime

Algorithms correlate rising vibration with heat patterns to predict bearing wear or cell imbalance. Edge computing raises immediate alerts while cloud analysis finds long-term trends and refines thresholds.

Integrating cloud analytics with edge alerts

Operations workflows link alerts to CMMS tickets, reserve parts, and schedule service windows. This reduces unexpected failures, extends component life, and lowers maintenance costs.

| Telemetry | Analysis | Action |

|---|---|---|

| Vibration, temp, battery | Edge anomaly scoring + cloud trend analysis | Immediate alert, scheduled service |

| Strain, RPM, environment | Correlation models for wear patterns | Parts pre-order, technician dispatch |

| Voltage/current logs | Cell imbalance detection | Battery swap before failure |

“A fleet avoided in‑flight failures after models flagged rising motor vibration, prompting a proactive service cycle.”

Iottive integrates sensor telemetry, edge alerts, and cloud analytics so teams gain clear monitoring, auditable logs, and training playbooks that keep compliance and performance aligned.

Flight Path Optimization and Dynamic Routing via AI

Real‑time route adaptation fuses live weather, traffic, and airspace notices to keep missions safe and punctual.

Multi‑source data fusion blends weather feeds, NOTAMs, terrain maps, and live ATC/UTM telemetry to build a per‑mission route that meets regulatory constraints and operational goals.

Live weather, no‑fly zones, and ATC integration

Routing engines ingest short‑term forecasts and temporary restrictions to reroute before a mission starts or mid‑flight. Integration with ATC/UTM systems and cloud dispatch pushes compliant paths directly to flight controllers.

Multi‑objective optimization: time, power, safety, compliance

Algorithms solve tradeoffs between fastest arrival, minimal energy use, and strict safety margins. Models use historical telemetry to predict headwinds and adjust altitude and speed proactively.

- Edge inference handles local obstacle avoidance and collision checks with millisecond processing.

- Cloud planning optimizes corridor‑level traffic and schedules across hubs.

- Automated training loops learn from completed missions to improve future route selection.

| Capability | Where it runs | Benefit |

|---|---|---|

| Immediate collision avoidance | Edge | Faster reactions, fewer detours |

| Corridor planning & scheduling | Cloud | Better throughput, predictable time windows |

| Headwind/energy models | Hybrid | Lower energy use, extended range |

Validation compares predicted routes to ground truth using telemetry analysis and accuracy metrics. Continuous dashboards show success rates and guide model retraining.

Hardware and systems require reliable GNSS/RTK, redundant sensors, and preflight health checks so paths execute as planned. These capabilities help operations reduce detours, save energy, and raise schedule predictability.

Computer Vision at the Edge: Faster Inspections and Safer Deliveries

Onboard vision systems shrink reaction times by running detection and classification where sensors collect data.

Onboard detection for autonomy in low-connectivity environments

Local processing lets vehicles navigate and complete delivery tasks when network links are weak. Edge computing performs object detection, landing‑zone checks, and obstacle avoidance with millisecond latency.

That resilience keeps operations moving and reduces the need to stream large volumes of data back to the cloud.

Thermal, LiDAR, and multispectral use cases

Sensor fusion combines RGB, thermal, LiDAR, and multispectral feeds to find people, spot heat anomalies, and verify safe drop sites. Algorithms weight each sensor by condition so systems remain accurate across varied environments.

Processing pipelines and hardware trade‑offs

Onboard pipelines run detection, classification, and lightweight tracking. Only compact results and selected frames are synced to the cloud, saving bandwidth and storage.

Choices between NVIDIA Jetson, Intel Movidius, and Qualcomm Snapdragon Flight balance compute, weight, and power to meet SWaP hardware requirements.

- Applications: infrastructure inspection, residential deliveries, and visual localization for precise landings.

- Accuracy: continuous calibration, seasonal domain adaptation, and field testing keep models reliable.

- Security: models reside in protected storage, streams can be encrypted, and signed packages secure model distribution.

Integration and operations

Edge-to-cloud patterns upload annotated evidence when connectivity returns for review and collaborative decision-making. Maintenance routines include camera health checks, lens-cleaning alerts, and scheduled recalibration via secure remote procedures.

“Local obstacle avoidance in a narrow alley caused an immediate reroute, then uploaded mission evidence for later analysis.”

drone OTA updates, IoT drone patching, AI drone performance tuning

Schedule installs during charging windows and low‑traffic periods to protect mission timing and customer expectations. Iottive implements scheduling that defers noncritical feature delivery until vehicles are idle or docked. That simple choice lowers downtime and keeps SLAs intact.

Scheduling strategies and background installs

Background downloads with prevalidation let devices fetch signed packages and verify checksums before any switchover. Dual‑partition switching then reduces visible disruption to a short reboot or partition flip.

Best practices include minimum battery thresholds, GNSS lock checks, and safe‑landing confirmation before final switchover. Watchdog timers and automatic rollback guard against install failures.

Compression, delta delivery, and bandwidth management

Delta and dictionary‑based compression shrink payloads and cut data transmission and costs. Depot multicast and peer‑to‑peer transfers in hangars improve bandwidth efficiency for clustered fleets.

CI/CD integration promotes signed artifacts, staged rollouts, and telemetry gates so telemetry validates installs before broader promotion. Co‑deploying models and sensors firmware prevents runtime conflicts and keeps perception stacks aligned.

- Power‑safe installs and thermal throttling protect hardware during processing.

- Dependency graphs and signature checks ensure software and model compatibility.

- Rollback + telemetry capture accelerate root‑cause analysis after failures.

Avoiding Common OTA Pitfalls in Drone Programs

Simple lapses—like unsigned packages or oversized payloads—cause the largest operational headaches.

Missing encryption, weak authentication, or absent integrity checks open fleets to tampering and service failures. Fix this with signed artifacts, checksums, and mutual certs so packages are verifiable before install.

Oversized payloads increase downtime during installs and raise failure risk in low‑bandwidth environments. Prefer incremental or delta delivery and depot multicast to shrink transfers and shorten mission impact.

Compatibility, staged rollouts, and success monitoring

Rollbacks and dual partitions prevent bricking after a bad install. Combine canary groups, phased rollouts, and telemetry gates to catch regressions early and limit blast radius.

System-level checks for firmware, application, and model versions stop runtime conflicts. Pre‑install resource checks and pause/resume for intermittent links reduce processing stress at the edge and cut downtime.

- Monitor install rates, crash spikes, and battery drain via dashboards and alerts.

- Plan for variable connectivity, temperature extremes, and vibration in field environments.

- Communicate change logs, operator schedules, and advance notices to crews.

Iottive bakes security by design, staged rollouts, telemetry, and automated rollback into end-to-end platforms to reduce risk across the entire lifecycle.

| Common issue | Mitigation | Operational benefit |

|---|---|---|

| Unsigned or tampered packages | Package signing + checksum validation | Prevents unauthorized installs |

| Oversized payloads | Delta delivery + multicast | Lower downtime, reduced bandwidth |

| No rollback plan | Dual partitions + automatic rollback | Reduces bricking and mission failures |

| Poor visibility | Telemetry dashboards + alerting | Faster remediation and trend detection |

Seamless Integration with Cloud and Mobile Platforms

When edge summaries stream to backend platforms, operators get instant context to guide scheduling and fixes.

Data pipelines, real-time monitoring, and fleet orchestration

Edge capture condenses sensor feeds into compact summaries that flow to cloud storage and annotation systems like Anvil Labs. This minimizes bandwidth while preserving actionable detail.

Real‑time monitoring feeds dashboards and orchestration engines. Operators see install status, health metrics, and delivery KPIs to schedule remediations or promote staged rollouts.

APIs, SDKs, and mobile apps for operations and maintenance

Integration patterns use REST APIs, gRPC, and SDKs to connect fleet controllers, update servers, and maintenance platforms. Containerized services and orchestration tools secure scalable workflows.

Mobile‑first tools—BLE provisioning apps and field diagnostics—let crews verify installs and trigger safe switchover at the pad. Role‑based access and audit logs keep management and compliance simple.

| Component | Function | Benefit |

|---|---|---|

| Edge processing | Summarize & prefilter sensor data | Lower costs, reduced latency |

| Cloud platform | Storage, annotation, orchestration | Scalable analysis, centralized management |

| APIs & SDKs | Integrate controllers and maintenance systems | Faster automation, repeatable workflows |

| Mobile apps | Provisioning and field control | Faster on‑pad operations, better connectivity |

Security and requirements include encrypted streams, certificate lifecycle management, and network segmentation to protect data and systems. Multi‑region infra, CDN, and IaC enable repeatable, compliant deployments.

Software lifecycle hooks automate build signing, policy checks, and staged promotions so releases meet policy gates before wide delivery. That seamless integration shortens time‑to‑value and reduces operational friction.

“Hybrid edge‑cloud pipelines turn raw telemetry into operational decisions while keeping costs and latency in check.”

Iottive offers Cloud & Mobile Integration, BLE App Development, and Custom IoT Platforms to unify telemetry, provisioning, and fleet operations. Contact: www.iottive.com | sales@iottive.com.

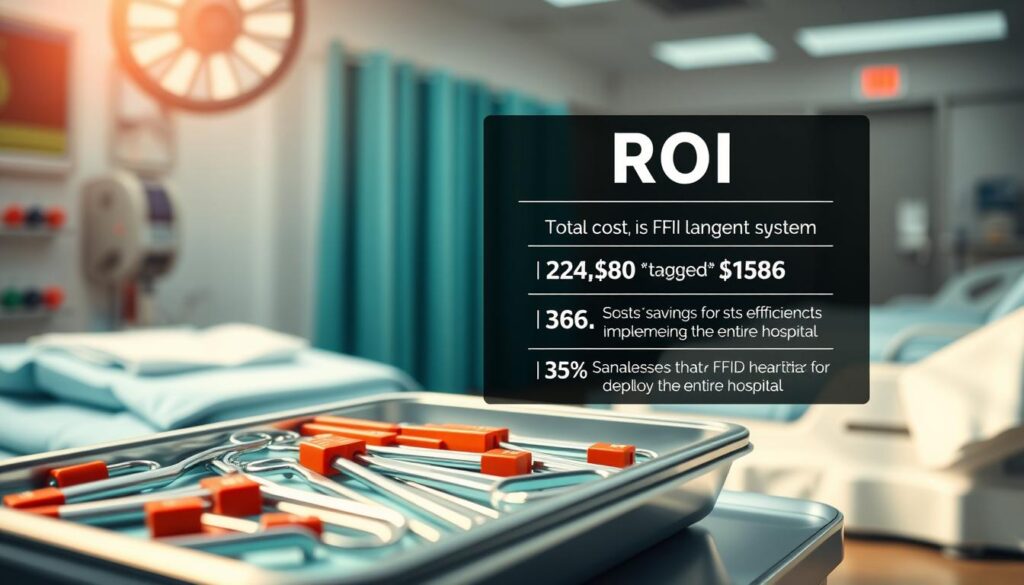

Cost, Uptime, and ROI: Making the Business Case

A clear ROI model ties fewer field visits and optimized bandwidth to measurable savings each quarter.

Reducing truck rolls, data transmission, and manual maintenance

Iottive quantifies cost savings from remote delivery and edge-enabled logic by modeling fewer depot visits, smaller payload sizes, and lower labor for scheduling and installs.

Edge summarization cuts raw data transfer by sending compact alerts instead of full streams. Background and incremental installs shrink visible downtime during service windows.

Measuring downtime avoided and performance gains

Dual-partition rollovers, staged rollouts, and automated rollback prevent fleet-wide outages and reduce mission interruptions.

Tie efficiency and performance to KPIs: on-time delivery rates, route adherence, and battery health trends. That links technical work to business outcomes and management reporting.

| Metric | What to measure | Business benefit |

|---|---|---|

| Truck rolls avoided | Number of field visits/year | Lower labor & travel costs |

| Bandwidth reduction | GB/month after edge summarization | Reduced data transfer costs |

| Downtime avoided | Minutes of service interruptions | Higher uptime, fewer SLA penalties |

| Maintenance events | Unplanned vs. predicted repairs | Lower spare parts and labor spend |

“Quantify baseline, pilot gains, and scaled impact to present a CFO-friendly business case.”

Where Iottive Fits: End-to-End IoT/AIoT for Secure Drone Updates

Iottive delivers a unified platform that connects BLE provisioning, cloud orchestration, and on-device processing.

This approach creates secure, auditable flows for software delivery, model distribution, and device lifecycle management.

BLE apps, cloud and mobile integration, and custom IoT platforms

Iottive’s solutions cover BLE-assisted provisioning, mobile diagnostics, and backend orchestration. Teams use these tools to manage versions, push signed artifacts, and verify installs with audit logs.

Edge capabilities include on-device inference, resilient caching, and model workflows that reduce bandwidth and speed remediation.

Industry-ready solutions and applications

Iottive builds systems for healthcare, automotive, smart home, consumer electronics, and industrial sectors. Each application is tailored for compliance and operational needs.

Hardware consulting guides SWaP-aware choices, storage sizing, and rugged designs to match field constraints.

Contact: www.iottive.com | sales@iottive.com

Management and maintenance dashboards unify telemetry, version status, and automated rollouts. This gives teams clear visibility and faster fault resolution.

| Capability | What it does | Benefit |

|---|---|---|

| Secure delivery | Signed packages, encrypted storage | Regulatory compliance and tamper resistance |

| Edge & model workflows | On-device inference, model rollbacks | Lower latency and safer deployments |

| Integration & data | APIs, telemetry pipelines, mobile apps | Seamless integration with existing systems |

| Hardware & support | SWaP guidance, durable designs, training | Faster time-to-value and sustained uptime |

“Trusted IoT, AIoT, and mobile app development that secures devices and streamlines fleet management.”

Conclusion

Conclusion

A resilient update strategy pairs centralized control with regional caches and on‑site validation to limit risk. Cloud-based delivery, reinforced by edge computing, forms the foundation for secure, efficient, and scalable delivery operations.

Signed, encrypted packages with dual partitions and incremental delivery protect safety and maintain system reliability. These measures, combined with AI-driven advancements in routing, predictive maintenance, and onboard vision, raise uptime and reduce costs.

Robust systems integration and smart computing placement cut latency and bandwidth use. Data‑informed decisions and continuous improvement shorten incident response and improve customer outcomes.

Iottive is ready to partner on secure end‑to‑end solutions—BLE apps, cloud/mobile integration, and AIoT workflows—to future‑proof delivery programs. Contact: www.iottive.com | sales@iottive.com.

FAQ

What are the main benefits of cloud-based updates for delivery drones?

Cloud-based delivery of software and firmware improves safety, reduces downtime, and speeds feature delivery. Centralized orchestration enables consistent security patches, telemetry aggregation for analytics, and scalable rollout strategies that cut operational costs and manual maintenance. This leads to better fleet efficiency, compliance, and faster time-to-value for new capabilities.

Why do continuous updates matter for fleets in a hyperconnected future?

Continuous updates keep devices secure, compliant, and operational as threats, airspace rules, and software expectations evolve. Regular delivery of fixes and model improvements prevents obsolescence, preserves data integrity, and ensures systems operate reliably with low downtime. They also support ongoing performance tuning and predictive maintenance driven by telemetry and machine learning.

How do over-the-air systems compare with manual servicing for fleet uptime and cost?

Over-the-air approaches minimize truck rolls and hands-on interventions by delivering patches and configuration changes remotely. This increases fleet availability, reduces labor and parts costs, and allows staged rollouts to mitigate risk. Manual servicing still plays a role for hardware failures, but remote delivery dramatically improves scale and time-to-repair.

What components make up a robust update architecture?

A resilient architecture includes an update server, device client, secure transport, and integrity verification. Best practices use dual-partition designs or rollback mechanisms to avoid bricking, incremental and multicast delivery to save bandwidth, and logging for monitoring. Edge nodes can offload heavy processing and reduce latency for large fleets.

Which secure protocols are recommended for transmitting update packages?

Use encryption and authenticated channels such as HTTPS and secure MQTT. For constrained links, CoAP with DTLS can be appropriate. Signatures, integrity checks, and strong key management ensure that only verified packages install on devices, protecting the supply chain and runtime environment.

Should organizations choose centralized, edge-based, or hybrid update models?

Centralized control offers simplicity and unified policy, but can create bottlenecks. Pure edge distribution lowers latency for time-critical fixes and on-site inference, while hybrid models balance scale, resilience, and cost. The right mix depends on fleet size, connectivity, regulatory needs, and compute constraints.

How do you prevent bricking during an update?

Implement dual-partition or A/B firmware schemes so the device boots from a known-good image if the new install fails. Include verification steps, staged rollouts, and rollback triggers. Maintain power-management safeguards and test updates in simulated environments before mass deployment.

What security measures harden the update pipeline end to end?

Employ code signing, mutual authentication, encrypted storage, and zero-trust device identity. Monitor for anomalies in delivery, rotate keys, and enforce least privilege in cloud components. Regular audits and automated compliance checks close gaps across the update lifecycle.

How do regulatory and safety requirements affect update practices in the U.S.?

Updates must support real-time coordination with airspace management (UTM) and respect temporary flight restrictions. Maintain documentation, audit trails, and versioned configurations to demonstrate compliance. Rapid distribution of safety-critical patches is often needed to meet regulatory expectations.

What role does edge computing play in update strategies?

Edge nodes enable on-site inference and preprocessing, reducing round-trip delays and bandwidth use. They accelerate decision-making—cutting response times from seconds to milliseconds—and can stage updates locally for intermittent connectivity. Hardware must account for SWaP constraints and durability.

How are AI models updated in the field without compromising privacy?

Use federated learning and privacy-preserving aggregation to improve models from distributed telemetry without sending raw sensor data to the cloud. Secure model signing, versioning, and validation prevent corrupt or adversarial models from degrading safety or performance.

How does predictive maintenance integrate with update systems?

Telemetry from sensors—batteries, motors, and structural stress—feeds cloud analytics and edge alerts. Machine learning flags anomalies and triggers targeted updates or maintenance actions. Integrating alerts with workflow and parts inventories reduces unplanned downtime and repair costs.

What techniques reduce bandwidth during mass rollouts?

Use delta compression, incremental patches, multicast delivery, and content-addressable distribution to limit transmitted bytes. Scheduling updates during low-traffic periods and using local edge caches further reduce data transmission costs and speed delivery.

How do teams measure ROI from remote update programs?

Track reduced truck rolls, decreased mean time to repair, improved uptime, and lower data transmission costs. Compare baseline maintenance spend with post-deployment metrics and quantify safety incidents avoided and operational efficiencies gained.

What are common pitfalls to avoid in remote update programs?

Avoid oversized payloads, missing rollback mechanisms, weak authentication, and poor compatibility testing. Lack of staged rollouts and insufficient monitoring can cause widespread failures. Plan staging, validation pipelines, and continuous monitoring to mitigate these risks.

How do platforms integrate with cloud and mobile tools for operations?

Modern platforms expose APIs, SDKs, and mobile apps for fleet orchestration, real-time monitoring, and maintenance workflows. They connect telemetry pipelines to analytics, support alerts, and provide role-based access controls to streamline operations and audits.

What infrastructure is needed to support secure, large-scale update delivery?

You need scalable cloud services for orchestration, content distribution networks, edge nodes or gateways, robust device identity systems, and monitoring stacks. Include incident response playbooks, automated testing, and compliance tooling to ensure resilience and regulatory alignment.

How can organizations ensure updates do not harm mission-critical functions?

Perform canary releases, staged rollouts, and real-world testing on representative hardware. Maintain clear fallback states, health checks, and automated rollback criteria. Coordinate release windows to minimize disruption to active operations.

What example use cases gain the most from advanced update strategies?

Time-sensitive delivery, medical supply transport, infrastructure inspection, and large-scale logistics all benefit. These environments need rapid patching, real-time routing, onboard vision updates, and predictive maintenance to preserve safety and service levels.

Which vendors or platforms are recognized for secure IoT update solutions?

Look for providers with proven device management, code-signing, and distribution capabilities, such as AWS IoT Device Management, Microsoft Azure IoT Hub, and Google Cloud IoT. Evaluate third-party specialists for edge orchestration, security hardening, and industry-specific compliance.

How do teams monitor success and detect failures after rollout?

Use telemetry dashboards, automated health checks, and alerting integrated with incident management. Track installation rates, error logs, rollback triggers, and performance KPIs. Correlate analytics with maintenance records to close the loop on fixes.

What are recommended scheduling strategies and fail-safes for background installs?

Schedule updates during low-activity windows, respect power and mission constraints, and allow pause/resume semantics. Include preflight checks, signature verification, and transactional install steps that can revert to the previous partition on failure.

How does compression and delta delivery affect onboard storage and compute requirements?

Smaller payloads ease storage and reduce processing overhead, enabling devices with limited memory and compute to accept updates. However, applying deltas requires verification logic and occasional temporary storage; design systems to meet these SWaP-aware constraints.

How can organizations balance cost, uptime, and resilience?

Adopt hybrid distribution, optimize bandwidth with deltas and multicast, and implement staged rollouts to limit blast radius. Measure trade-offs between centralized simplicity and edge resilience, then align architecture to expected scale and regulatory demands.

How does iottive support end-to-end update and device management?

iottive provides BLE apps, cloud and mobile integration, and customizable IoT platforms that handle secure delivery, device identity, and telemetry pipelines. Their solutions support healthcare, automotive, industrial, and smart-home use cases with integration tools, monitoring, and compliance features.